Characteristics

| Magnetic Parameters | |

|---|---|

| Bending power | ∫Bdl = 4 Tm (10 m track length) |

| Non-uniformity of ∫Bdl | ≤±5% in acceptance (hor.: ±300 mrad, vert.: ±250 mrad) |

| Excitation current | NI = 2 × 1.3 MA |

| Electric power dissipation | Pe = 4.2 MW |

| Stored magnetic energy | Wm≈32 MJ |

| Inductance | L ≈ 2 H |

| Coil and Curent | |

| Coil structure (two coils) | 15 mono-layer pancakes per coil |

| Total number of turns | N = 2 × 225 |

| Conductor material | Aluminium Al-99.7 |

| Conductor cross-section | 50 mm × 50 mm |

| Cooling water channel | ∅ = 24 mm |

| Conductor length | Lc≈290 m per pancake |

| Current in conductor | I ≈ 5.8 kA |

| Current density | σ ≈ 2.9 A / mm2 |

| Total resistance | R = 125 mΩ @ 20°C |

| Total voltage drop (two coils) | U ≈ 730 V |

| Cooling | |

| Cooling requirements | all pancakes in parallel |

| Total water flow | Φ ≈ 125 m3/h |

| Pressure drop of cooling water | Δp ≈ 10 bar @ ΔT = 30°C |

| Mechanics | |

| Steel quality of yoke | EN S235JR, (old norms: Fe360B, St37-2) |

| Outer yoke dimensions | hor × vert × beam: 11 m × 8 m × 2.6 m |

| Useful wedged aperture (upstream ⇒ downstream) |

hor: 2.6 m ⇒ 4.2 m vert: 2.2 m ⇒ 3.5 m |

| Total magnet extension in beam direct. | Lm ≈5 m |

| Weight of yoke | My ≈1450 ton |

| Weight of coils | Mc ≈ 2 × 25 ton |

Field map and measurements

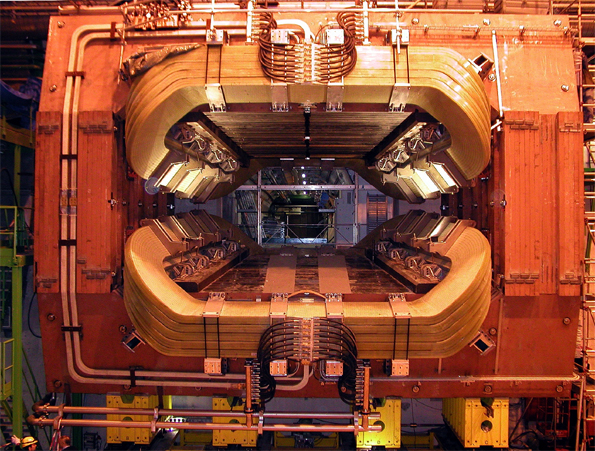

Pictures

Installation of the LHCb dipole yoke, lower part.

LHCb coil, turning lower one by 180°

LHCb dipole magnet installation completed!